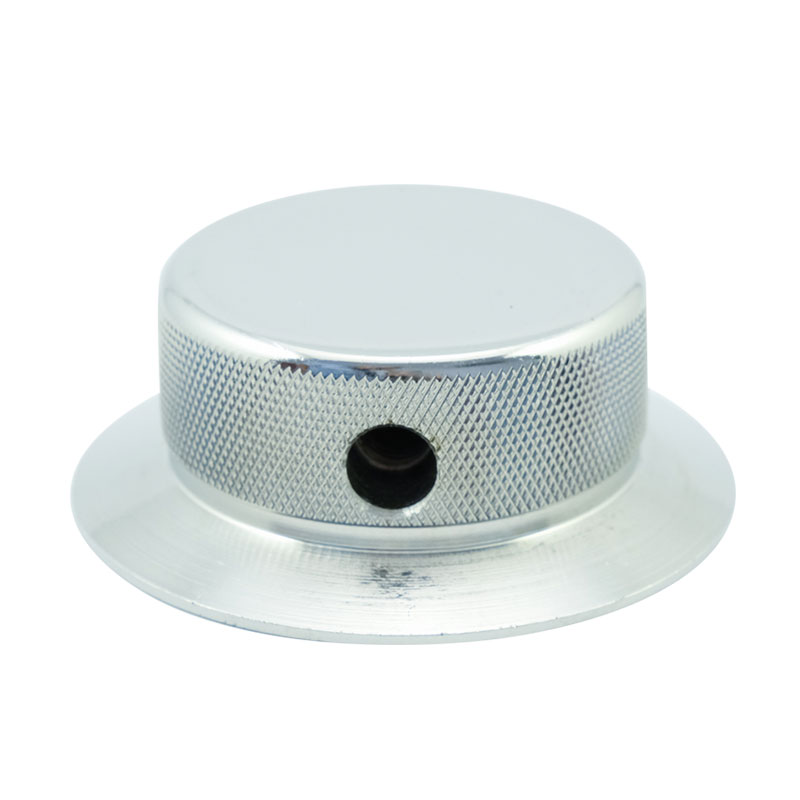

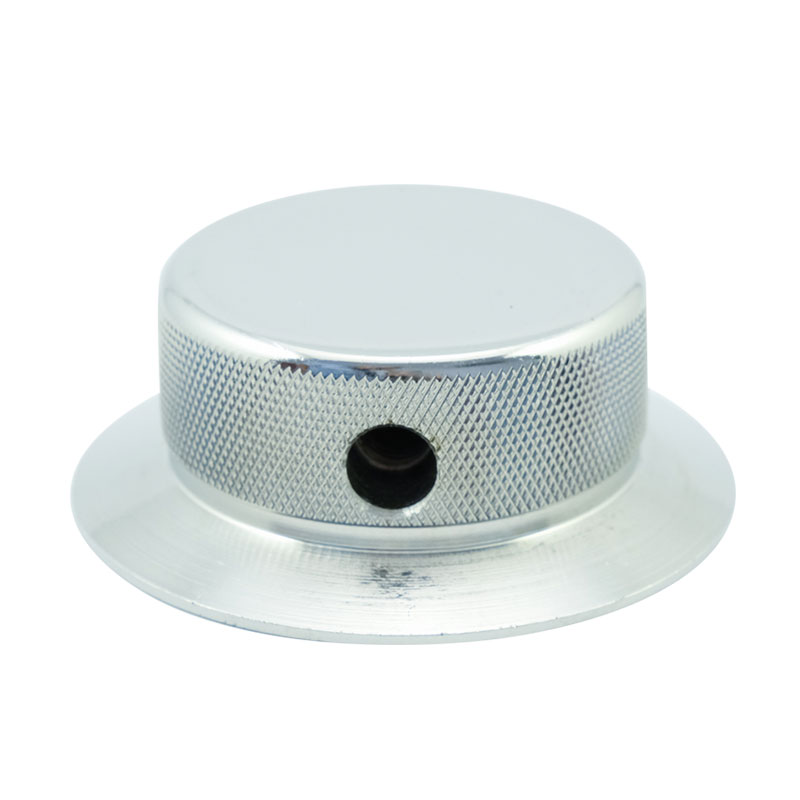

Summary:Having precision machining parts means you will be able to create the best products possible. These ...

Having

precision machining parts means you will be able to create the best products possible. These components are made to the exact specifications of your product. They are highly accurate and can be produced in large quantities.

A precision machining process will include a Computer Numerical Control (CNC) machine, which uses advanced equipment to produce small parts that are highly accurate. These machines are ideal for nearly every industry.

Precision machining is used in many industries, including the aerospace and medical industries. In addition, CNC machining can be used to produce a variety of other components, including auto parts, which combine computer and measurement technology.

The aerospace industry, for instance, is required to have extremely accurate parts. In addition, aerospace equipment is often made from expensive metals that require precision machining technology.

The defense industry is also a good example of an industry that requires high accuracy. The defense industry's applications range from new weapons prototypes to entire missile systems. This industry also requires equipment that can be made from rugged materials.

Precision machining parts are also useful for the medical industry, which requires products that have perfect precision. This allows doctors to perform joint replacements. They cannot afford to have space for errors.

A computer-aided design (CAD) program can help you create a graphical model of the part, which is easier to understand for designers. These programs are free to use. They can also be used to create 2D and 3D models. You can also specify tolerances on your digital designs.

Main:+86 574 87907106

Main:+86 574 87907106![]() Main:+86 574 87907106

Main:+86 574 87907106