Summary:Processing characteristics and processing objects of CNC lathes:1. High-precision parts processing o...

Processing characteristics and processing objects of CNC lathes:

1. High-precision

parts processing of CNC lathesThe accuracy requirements of parts mainly refer to the accuracy requirements of shape, size, position and surface, and the surface accuracy mainly refers to the surface roughness. Ultra-precision parts such as the rotating drum in the copier, the magnetic head on the video recorder and the polyhedral reflector on the laser printing, the body contour accuracy is as high as 0.01um, and the surface roughness value is Ra0.02um. These high-precision parts can be processed on a special precision CNC lathe.

2. Highly difficult machining of CNC lathes

Forming surface parts, non-standard pitch (or lead), variable pitch, constant pitch and variable pitch, or spiral parts with smooth transition between cylindrical and conical spiral surfaces can all be processed on a CNC lathe.

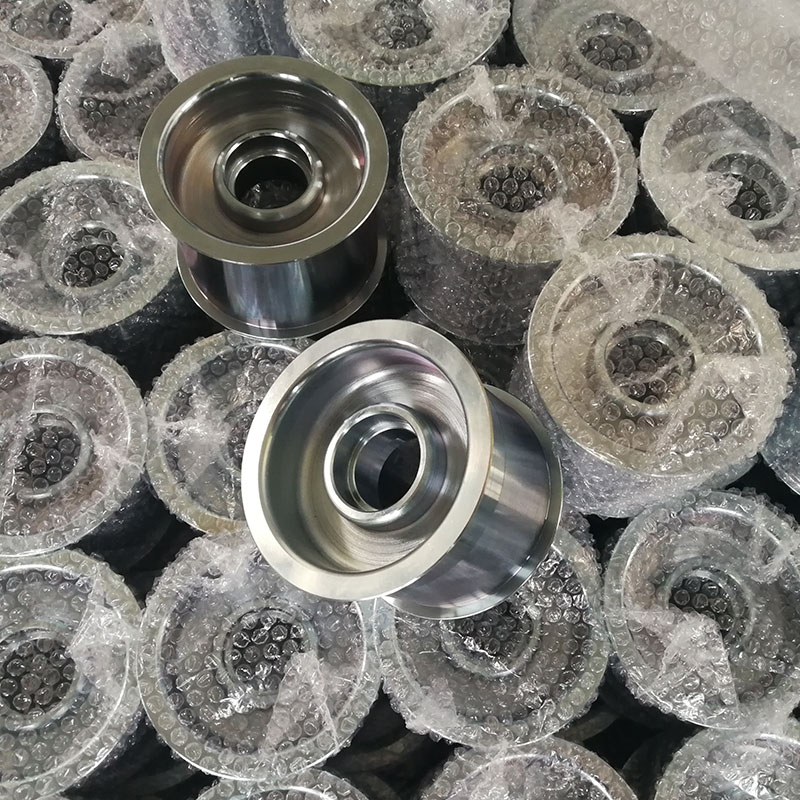

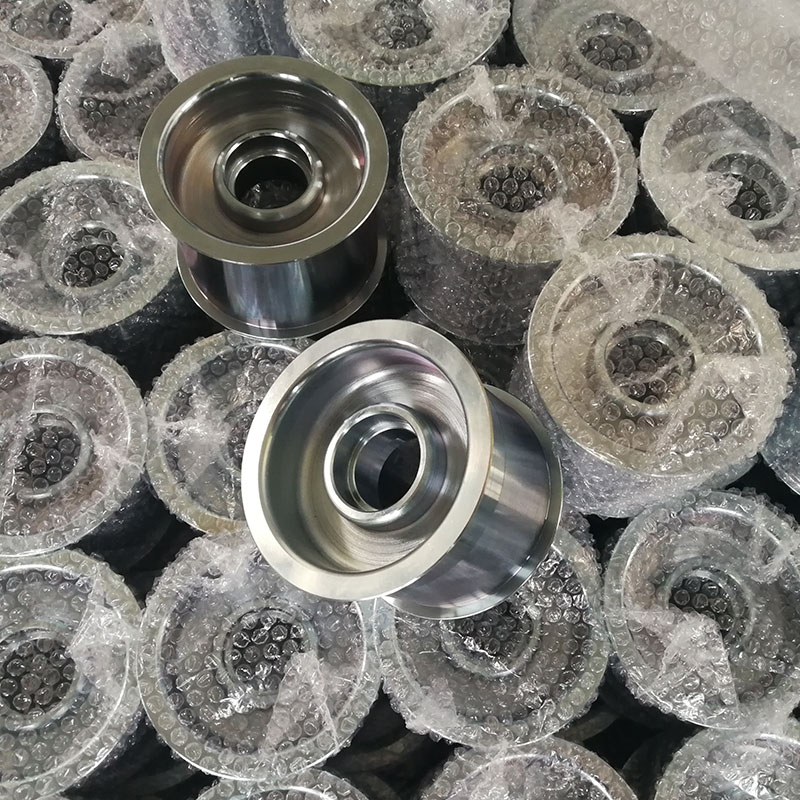

Examples of special inner surface parts

3. High-efficiency machining of CNC lathes

In order to further improve the efficiency of turning processing, by increasing the control axis of turning, it is possible to simultaneously process two multi-process identical or different parts on a CNC lathe.

4. Machining of hardened workpieces on CNC lathes

In the processing of large molds, there are many parts with complex shapes and large sizes. However, the deformation of these parts after heat treatment is relatively difficult, and the grinding process is somewhat difficult. On the CNC lathe, the hardened parts can be turned with a ceramic turning tool, and the turning is used instead of grinding, thereby improving the processing efficiency of the CNC lathe.

Main:+86 574 87907106

Main:+86 574 87907106![]() Main:+86 574 87907106

Main:+86 574 87907106